Honda XL650V Transalp Rally Conversion: Full Custom Makeover for Adventure Enthusiasts

After years of experience in the fairings production industry, we decided to take on a massive project—transforming the classic Honda XL650V Transalp into a modern, rally-ready adventure bike. The demand was overwhelming, as we received countless messages from customers asking, “When will the Transalp 650 be ready?” Today, the wait is over, and we’re proud to introduce our Honda XL650V Transalp Rally Conversion.

The time had come for the Transalp 650 to get the transformation it truly deserved—a brand-new look and upgraded performance for the most demanding riders.

Finding the Right Base for the Honda XL650V Transalp Conversion

The search for the right Honda XL650V Transalp was a challenging one. We reviewed dozens of bikes, many of which appeared brand new externally but were far from perfect for a rally conversion project. In our case, cosmetic appearance wasn’t a priority—engine condition was the key factor. After careful consideration, we finally found a used bike that seemed to be abandoned, but its engine was still in excellent shape.

The previous owner had used the bike daily for commuting, but had neglected the cosmetic aspects (broken fairings, missing windshield, etc.). This made the bike a perfect candidate for our rally conversion, as we could focus on performance and completely revamp the appearance.

Initial Assessment and Testing: Ensuring the Bike’s Performance

Upon purchasing the Honda XL650V Transalp, we performed thorough testing to evaluate its performance. The engine ran smoothly, and the suspension, chain, and other vital components were in great condition. This gave us the green light to begin disassembling the bike, knowing that the mechanical parts would perform well once we enhanced the bike’s design and durability.

Stripping Down the Transalp: Starting the Rally Conversion Process

The first step was to strip the bike down to its frame. We began by removing all the fairings and the engine guard. This was essential to evaluate which parts we could retain and which ones we needed to upgrade for the rally build. Once the bike was completely disassembled, we moved on to removing more complex parts like the rear swing arm, brakes, and various other components.

The next step was to send the parts that would need electrostatic coating to a specialist. Electrostatic coating is a durable and corrosion-resistant treatment that protects the bike from harsh conditions, making it ideal for off-road use.

Electrostatic Coating and Upgrading the Wheel Rims

When the parts returned from the electrostatic coating, the transformation was already taking shape. While the bike still had its original blue fuel tank, we knew there was still plenty of work to do.

The next task was upgrading the wheel rims. To ensure maximum strength and safety during off-road riding, we installed new spokes—much thicker than the stock spokes. These thicker spokes would provide enhanced durability and help the bike handle rough terrains with ease.

Upgrading the wheel rims required specialized work, and we enlisted a professional to help us with the installation. The process involved deep cleaning the rims and applying a double-coating finish. We also added new off-road tires from our shop to get the bike ready for any adventure.

Performance Enhancements: Replacing Critical Parts

With the wheels and rims complete, we moved on to other critical performance upgrades:

- Brake Discs and Brake Pads: We replaced the worn-out brake components with high-performance brake discs and pads designed to handle the demands of off-road and rally riding.

- Chain and Sprockets: We replaced the chain and sprockets with heavy-duty versions that would withstand the rigors of off-road conditions, ensuring reliable power transfer.

- Suspension Upgrades: We evaluated the stock suspension and made adjustments to suit the demands of off-road riding, ensuring the bike could handle rough terrain without compromising ride comfort.

These upgrades were critical for ensuring the Honda XL650V Transalp would perform as expected in challenging rally environments.

Custom Parts and Design: Creating the Perfect Rally Bike

With the base bike now upgraded for performance, we began focusing on creating the custom parts that would truly give the Honda Transalp 650 its rally-ready look. Some of these parts were designed from scratch, while others were custom-modified to fit the bike’s new specifications.

We used the latest technologies to make this process faster and more precise:

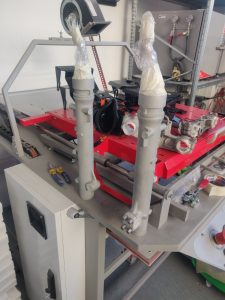

- 3D Scanning: We scanned the entire bike to create digital models and ensure the custom parts would fit perfectly.

- Computer-Aided Design (CAD): Using CAD software, we designed the new navigation tower, engine guard, and other key components to meet the requirements of a rally bike.

- Traditional Handcrafting: For the fairing, we decided to go the traditional route and handcraft the part, just like we do with all our custom builds. This method gives each bike a unique and personal touch.

Here are the key custom parts we developed for the Honda XL650V Transalp Rally Build:

- Navigation Tower: A crucial element for rally bikes, this tower holds the headlights, speedometer, and provides a solid base for the windscreen.

- Engine Guard: A custom-designed guard to protect the bike’s engine during rough off-road rides.

- Chain Guard: Protects the chain from debris and mud while riding on rugged trails.

- Radiator Inox Grills: Made from stainless steel, these grills prevent rocks and debris from damaging the radiator while maintaining optimal airflow.

- New Fairing: A sleek, rally-inspired fairing that provides better aerodynamics and enhances the bike’s aggressive rally aesthetic.

- Rear Fender: Designed for durability and a clean, modern look, this new rear fender is perfect for handling the tough conditions of rally riding.

- Rear Soft Luggage Rack: Ideal for carrying luggage on long-distance journeys, this custom rack is designed to fit seamlessly with the bike’s rear end.

Final Touches: Painting, Electrical Upgrades, and Testing

Once the custom parts were ready, we began the final assembly process. This included:

- Painting: We gave the bike a fresh, bold paint job that reflects the rally-inspired design while maintaining the Honda Transalp’s heritage.

- Electrical Work: The new speedometer was installed, and we made various electrical upgrades to ensure the bike’s system was ready for adventure.

- Final Testing: After putting everything together, we conducted extensive road tests to ensure all components worked flawlessly. This included fine-tuning the suspension, brakes, and electrical systems.

The project took over 5 months to complete, involving countless hours of hard work, testing, and revisions to get everything just right. We had to overcome challenges such as faulty parts, design issues, and prototypes that didn’t meet our expectations. But in the end, the results were worth it: a Honda XL650V Transalp Rally that was ready for any off-road adventure.

Ready for Your Own Rally Conversion?

If you’re looking to transform your Honda XL650V Transalp or any other adventure bike into a rally-ready machine, we are here to help. We specialize in custom rally bike conversions and offer a wide range of high-performance parts to suit your needs. From navigation towers and engine guards to rally fairings and custom luggage racks, we have the expertise to bring your vision to life.

Contact us today to start your own rally build and make your adventure bike ready for the toughest terrain!

LINK FOR THE KIT :

Honda XL650V Transalp Rally Conversion: Full Custom Makeover for Adventure Enthusiasts